Why molded fiber?

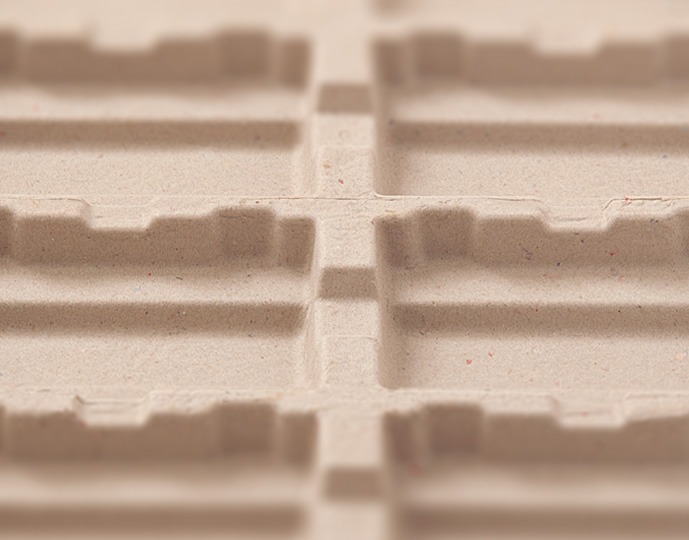

More and more companies look for eco-friendly materials with an easy disposal route. Materials that maximize the use of post-consumer recycled content. Materials that combine sustainability with efficiency. Look no further. Molded fiber (also called molded pulp) is your solution. Molded pulp can be applied to almost all industries, from medical supplies to food packaging, and from design objects to secondary packaging applications. It’s the natural alternative to fossil fuel-based packaging solutions and its’ applications are limitless.